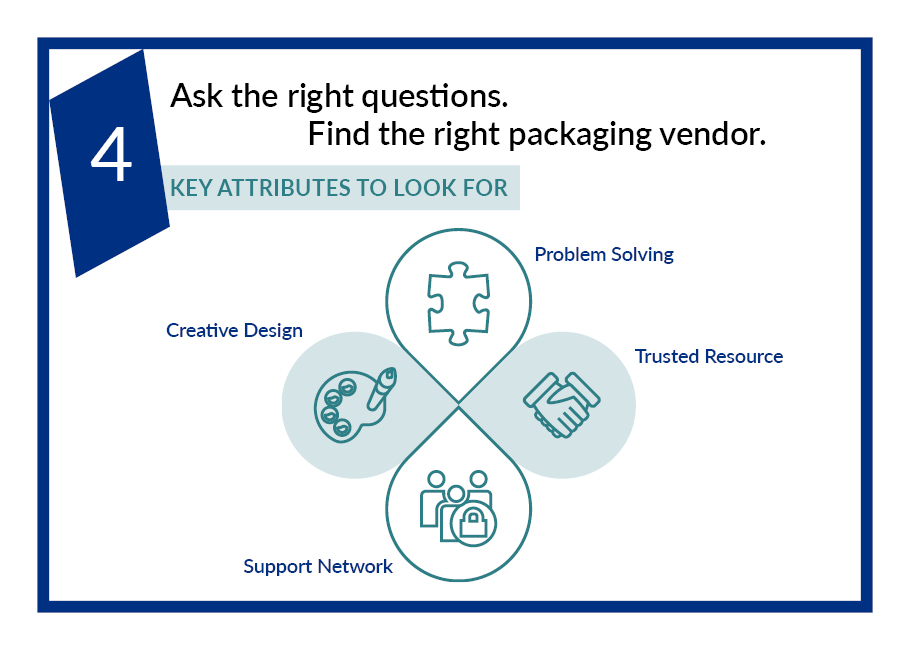

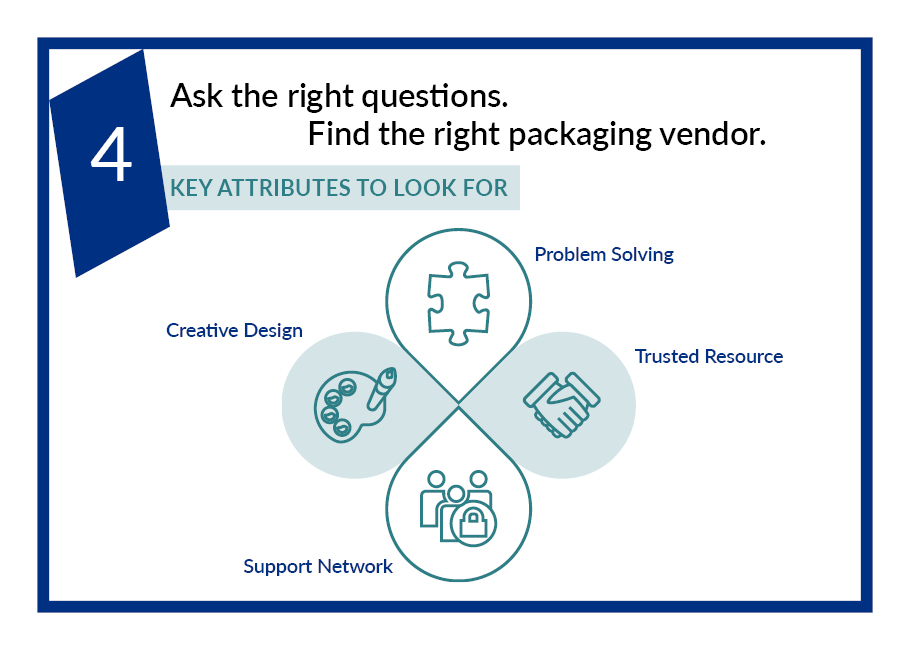

Find the Right Packaging Vendor

1. Problem Solving

You’ve been there before. A packaging company submits a quote before understanding your business. They may save you pennies on materials but miss out on saving you dollars where it matters most.

What to ask. |

Why ask? |

| Does the size of my business matter? | You don’t want to be pushed aside by your vendor’s obligation to their larger customers. |

| What differentiates your packaging company from the competition? | If the answer is, “We offer the lowest price,” watch out. Be sure you are getting the best solution. It will result in more overall value in the long run. |

| What is your backup plan for taking care of my packaging needs during peak times? | Duplicate equipment and a nearby backup location means no downtime or delays in your business. |

2. Creative Design

Custom design means your packaging is best suited to your needs. Too many times packaging solutions are designed to best fit the manufacturer’s capabilities.

What to ask. |

Why ask? |

| Where are your design centers located? | Look for partners with more than one design center and design resources located near the manufacturing facility producing your packaging. This means less wait time and better collaboration with your team and the manufacturer. |

| Do you have in-house testing capabilities? | In-house resources shorten lead times and provide more opportunity to test a range of solutions. |

| What are the different corrugated packaging options (i.e., materials, printing, packaging styles, etc.) that you offer? | You want to select a vendor who can provide solutions that fit your needs rather than one that is limited by their capabilities. The more options, the more likely a better fit for you. |

3. Trusted Resource

Look for a packaging partner willing to invest the time and resources to proactively bring ideas that will strengthen your business. This means they are in it for the long haul and not just focused on transactional business.

What to ask. |

Why ask? |

| How do you seek feedback from your customers? | It’s important to have a supplier that is responsive to your needs and builds long-term relationships with their customers. |

| How many customers do you have? | You need to understand how much of your vendor’s business is dedicated to its largest customers. This information will provide a clear understanding of how much attention will be dedicated to your account. |

| How can you help drive efficiencies and results in my business? | You want a packaging partner that doesn’t just focus on material costs, but looks deeper. It’s important that they have the resources to help you identify costs savings throughout your supply chain. |

4. Support Network

Packaging partners that control their paper supply and manage specific contingency plans for operations will deliver on time and on budget.

What to ask. |

Why ask? |

| Where does your company source its containerboard? | Companies that manufacture their own containerboard control the entire process, offering consistent quality and uninterrupted supply. |

| Who is my point of contact? | It’s important to have a point of contact near or at each manufacturing facility who can directly see your packaging through the entire process. But if you purchase through multiple facilities, you should also have one primary point of contact in order to streamline communications. |

| Is your manufacturing facility close to my delivery location? | Having your packaging manufactured nearby can reduce delivery times, save on transportation costs and reduce your carbon footprint. |