Nowadays, convenience is king. From the advent of fast food to the technology that streamlines our day-to-day activities, we crave the instant gratification and simplicity that convenience offers. But this era of convenience has consequences that can be harmful to the environment. From the on-the-go packaging that simplifies eating on the run to our daily doorstep deliveries that make leaving the house passé, the convenience that packaging brings has become a worldwide problem. According to the U.S. Environmental Protection Agency, more than 82 million tons of packaging was produced in 2018.

Nationwide retailers like Walmart and Amazon are making great efforts to significantly reduce the amount of plastic and corrugated in their supply chains, which can then end up in the waste stream. With lofty goals of zeroing their emissions and reducing waste, changes in their packaging can be seen in everything from their brick-and-mortar produce departments to their e-commerce delivery. Implementing efficiencies throughout the supply chain to reduce waste is commendable; however, sometimes it’s difficult to see the forest through the trees.

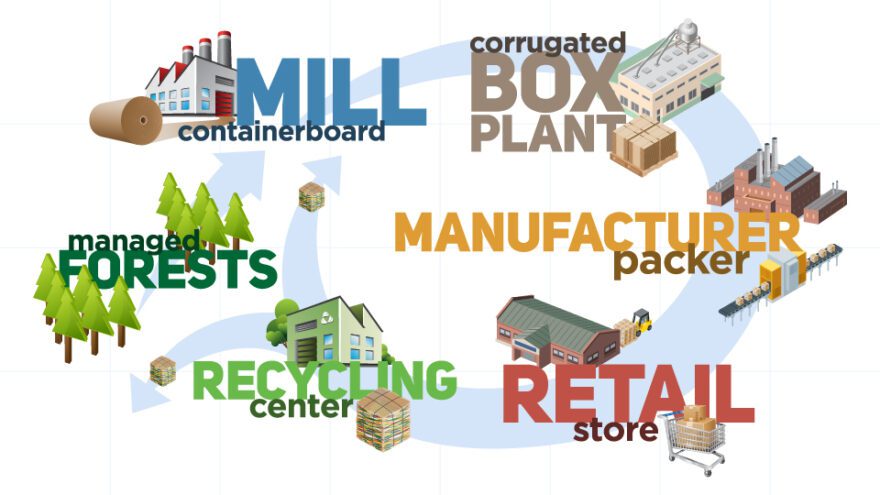

Corrugated is often vilified for its one-time use, even though its fibers can be used 5–7 times through recovery and recycling efforts. As a result, some retailers are requiring a reduction in corrugated use and mandating plastic reuse in their sustainability efforts. But comparing corrugated and its one-time use to other products like reusable plastic is like comparing apples to oranges. Corrugated was sustainable long before sustainable became a forethought, and it will remain the most sustainable option available long after other products have their day in the sun. Let’s review why corrugated always was and always will be the most sustainable option from start to finish.

It Doesn’t Get More Natural Than a Tree

Did you know that corrugated is manufactured from trees? And those trees are a renewable resource. To understand the benefits of using a renewable resource, it’s important to recognize the capabilities of a tree in its natural state and how the production of corrugated can be seen as far more beneficial to the environment than other materials like plastics.

Just like corrugated packaging works to contain products, trees and forests could be considered a form of packaging. Trees are the most efficient natural system for carbon storage. They pull carbon dioxide (CO2) out of the atmosphere and store it. Reducing CO2 in our environment is key to mitigating climate change, making forests and trees vitally important. Knowing the overall importance of forests in the fight against climate change, it would seem that cutting down trees to make packaging is counterproductive to sustainability. On the contrary, young trees have been found to be even more efficient at absorbing CO2 than older trees. So as it turns out, planting, harvesting and replanting forests is more environmentally effective than just letting forests age.

Most corrugated manufacturers are dedicated to managed forestry in their efforts. With managed forestry, in the U.S. alone, more than one billion seedlings are planted each year.* That equates to more than 2.7 million new trees every day. Managed forestry means that more trees are being planted than harvested. According to the Food and Agriculture Organization, the U.S. has more trees now than it did 100 years ago.

Corrugated companies like Packaging Corporation of America (PCA) are committed to managed forestry. As a top priority in their sustainability efforts, most are certified by the Sustainable Forestry Initiative® (SFI) program, which holds them to rigorous standards for responsible forest management.

Using Byproducts for Energy

It’s no secret that manufacturing processes of any kind can have a negative effect on the environment. From industrial waste being thrown into landfills to toxic materials that destroy soil, the production of 21st-century products can negatively impact the Earth’s atmosphere, soil, water and more. And no manufacturing industry is free from blame, but let’s look at where corrugated shines.

During the corrugated manufacturing process, tree bark is removed, collected and used as a fuel to generate steam and electricity for the mills. The residual sawdust and small chips from the trees are also collected and used for energy. Essentially all the trees’ byproducts are captured to fuel the mills that take part in the manufacturing of corrugated. At PCA over 60% of its mills’ energy needs are generated from byproducts of the manufacturing process.

Additionally, corrugated companies like PCA work with industry organizations like the Fibre Box Association and the American Forest & Paper Association (AF&PA) to support the industry’s progress on sustainability. With common goals of net-zero emissions and a reduction on the reliance of fossil fuels, the industry continues to increase its use of biobased fuels in containerboard production and converting. The corrugated industry has been steadily increasing both recovery and biogenic fuel use over decades.

The industry is committed to catalyzing industry-wide change that will preserve both people and the planet.

Number 1 in Recyclability and Recycling Rates

Corrugated is sustainable in how it is sourced and manufactured, but equally important, corrugated is highly recyclable and has a long history of being recycled. Recycling corrugated can be dated back to the 19th century; however, it became more common in the 70s and 80s. According to AF&PA, corrugated is the most recycled packaging material in the U.S., with more than 34 million tons of OCC (old corrugated containers) being recycled in 2021. In 2022 approximately 93.4% of all corrugated products were recovered and directed into the recycling stream. With the corrugated recycling rate hovering around 90% or more for more than a decade, it would be hard to argue that there is any other material that offers greater sustainability.

As the most recycled packaging material, corrugated can be recycled and reused 5–7 times. On average, newly manufactured corrugated products industry-wide contain about 52% recycled fiber, which includes both post- and pre-consumer fiber. And the balance of all recovered corrugated goes to support the needs of industries for other paper-based products. In fact, the AF&PA reported that in 2021, 80% of all mills used some amount of recycled paper to make new and essential products.

Sustainable Then, Sustainable Now, Sustainable Indefinitely

As companies continue to incorporate ecofriendly mindsets and practices in all that they do — including reevaluating their packaging to make improvements — it’s important to understand that different types of packaging offer different benefits and consequences. To make a truly informed decision, retailers need to understand the full story. When it comes to achieving sustainability goals, corrugated outperforms plastics (reusable or not) every single time.

For more information, please contact us by completing the form below.

*Source: North American Forest Foundation, Tree & Wood Facts