With the COVID-19 pandemic forcing many consumers to keep their vehicles longer than usual, along with an increased demand for used-car inventories, there’s been a steady increase in the need for auto parts. PCA has an experienced, dedicated team focused on providing out-of-the-box solutions for the automotive industry.

“PCA has a particular advantage when it comes to working with Tier 1 OEM suppliers,” says PCA General Manager Chris Pannecouck. “Because we produce large-format palletized boxes, we can deliver many more possibilities for automotive suppliers.”

PCA’s full-line facilities produce heavy-duty corrugated shipping materials, a necessity for automotive parts suppliers. These manufacturing plants specialize in triplewall corrugated that is significantly stronger than normal shipping boxes. Other specialties benefiting automotive OEM suppliers include:

- Large shipping containers

- ExportPack™ (preassembled packaging for overseas shipment)

- Multi-color printing

- Expendable shipping containers

- Custom builds and kit bundling

- Bulk boxes

- Hazardous materials packaging

Bulk-Shipping Design Team Focuses on OEM Solutions

The real differentiator, however, comes down to expertise, Pannecouck says. A dedicated bulk-shipping design team works directly with automotive OEM customers. Together, they quickly identify, troubleshoot and eliminate the biggest challenges facing bulk shippers—damaged goods, excessive shipping and material costs. The goal of the team and their innovative efforts is to protect automotive parts from the moment they leave the production line until they’re in the hands of the end user.

“Our three-person design team from the Plymouth, Michigan, plant drives competitive advantage for our partners seeking bulk or heavy-duty packaging,” Pannecouck says. “They have a combined 60 to 70 years of experience. If there’s a part on a vehicle, I’m positive we’ve designed an individual box or a multi-pack for it. We’ve seen it all.”

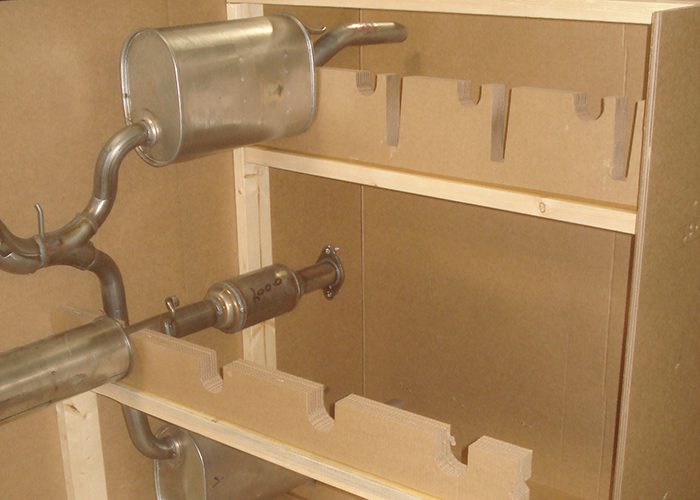

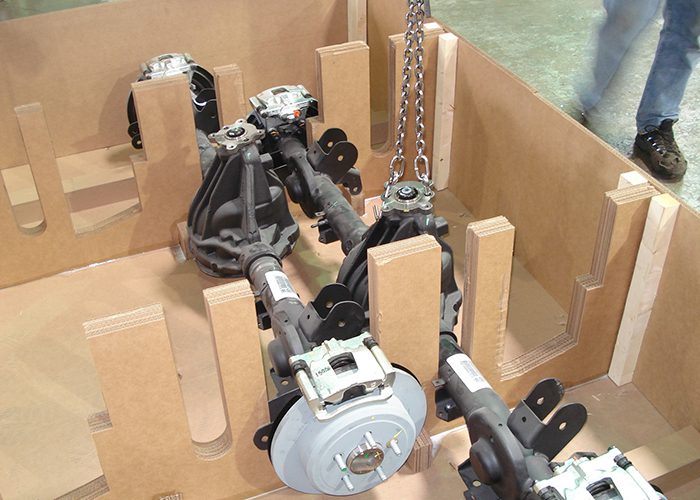

That’s not an exaggeration. Pannecouck can rattle off a long list of automotive parts the PCA team has designed custom packaging for, from bolts to bulky wheels to heavy, awkward items like engines, frames, axles, exhaust systems and transmissions.

Custom Packaging and Shipping

The most challenging shipments often require custom hand-assembled packaging configurations. These kits include specialized pallet assemblies, wood corners for extra protection, wooden posts to support excessive weight and foam protection.

According to Pannecouck: “Many times we build and assemble custom box configurations in our warehouse before shipping to customers. That all takes a significant amount of time and resources. We feel this differentiates us in the marketplace. We even seek out customers who want custom packs for specific parts.”

Other PCA heavy-duty and bulk packaging advantages include:

- Warehouse space for just-in-time (JIT) delivery

- Lighter, expendable alternatives for overseas shipments, replacing the need for returnable plastic containers or metal racks

- Bank builds—a “bank” of parts set aside for cars no longer in production

- A testing lab in Vernon Hills, Illinois, that conducts vibration and incline tests to ensure quality, safety and protection

In short, PCA can design a bulk, heavy-duty shipping solution for automotive parts in any size, weight or configuration.

To learn more about PCA’s automotive OEM packaging capabilities and specialties, please contact us.