How Corrugated Boxes Are Made

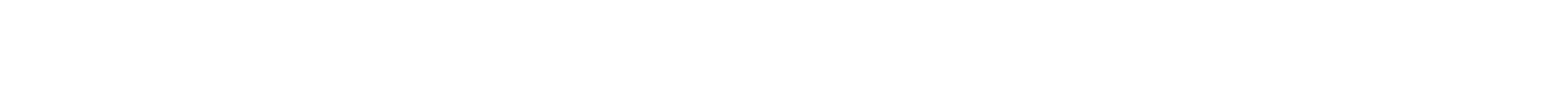

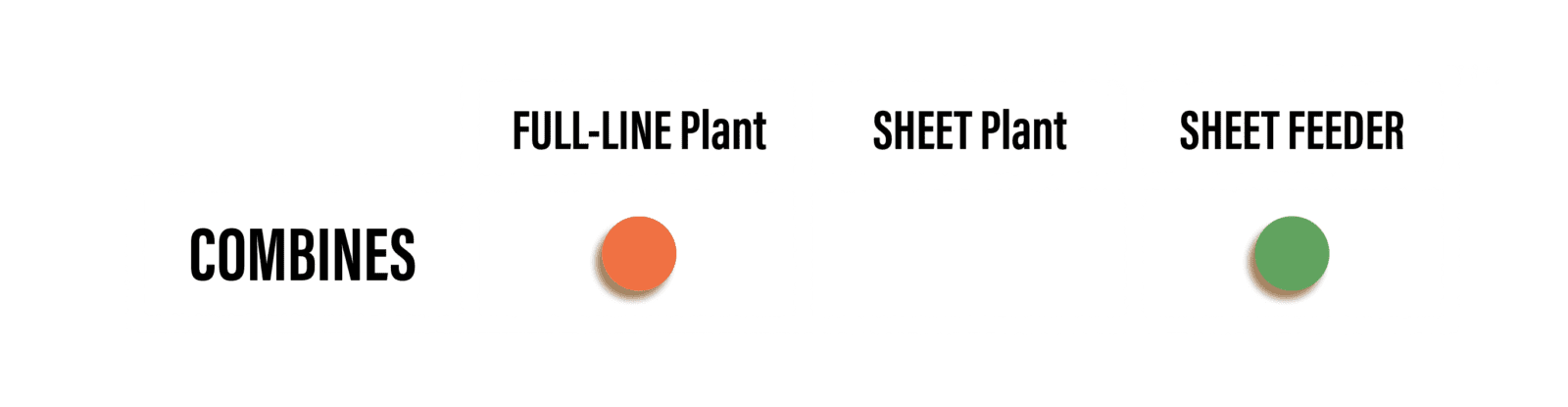

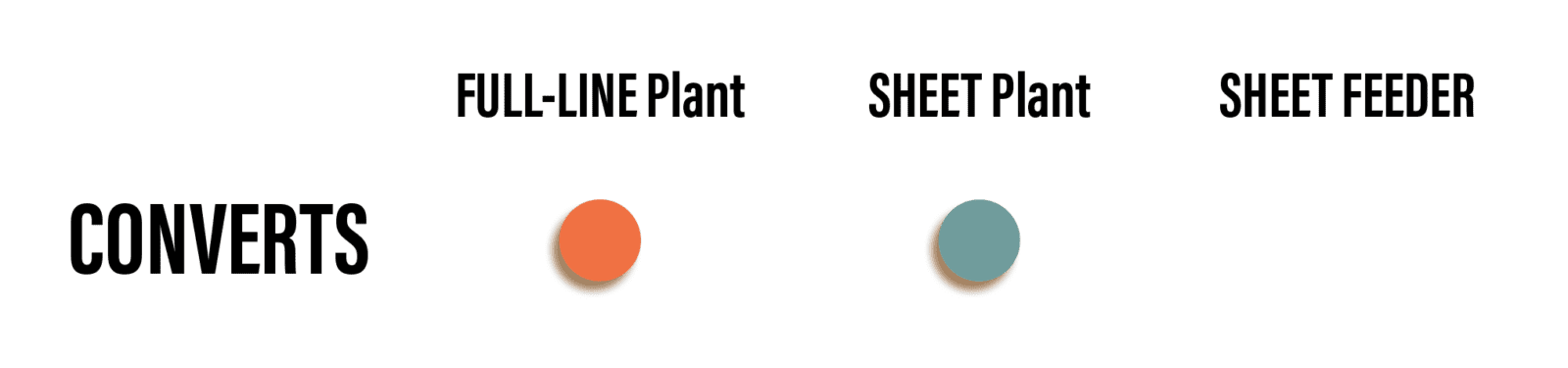

3 Types of Plants.

3 Different Workflows.

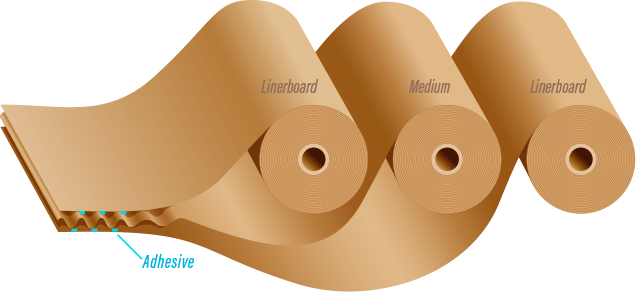

Linerboard, Medium, Flutes and Starch

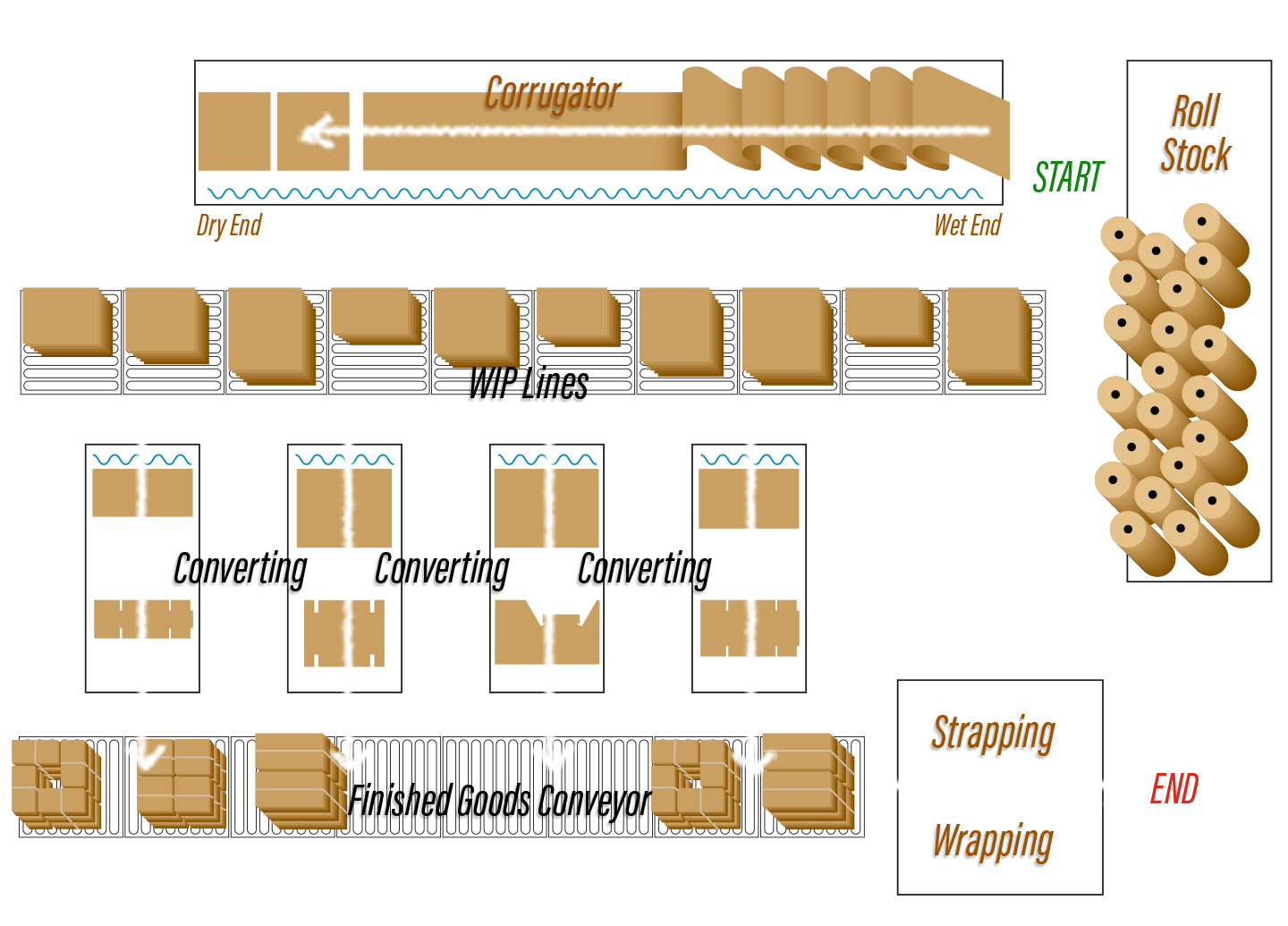

the combining stage — a parallel process

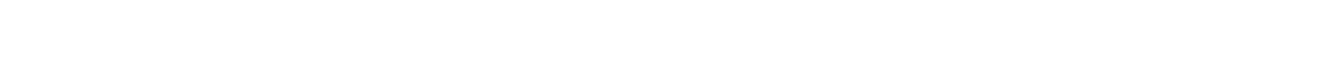

Combining is putting the layers of linerboard and medium together to form complete corrugated board.

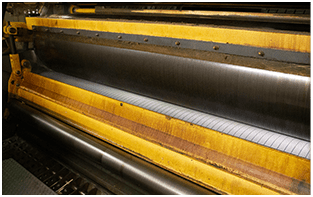

Medium is engineered to form easily into flutes as it is fed between two large gear-like rollers on the Wet End of the corrugator.

Linerboard is engineered to remain flat as it adheres to the top and bottom of the fluted medium by means of starch-based adhesive.

When combined, these two materials become the amazingly strong structural material that is corrugated board.

equipment:

Corrugator

- Combines linerboard and medium into corrugated board

- Cuts sheets to overall job size

- Can put straight-line scores across flutes

- Can make variety of flute profiles

- Can make variety of board types: singlewall, doublewall, etc.

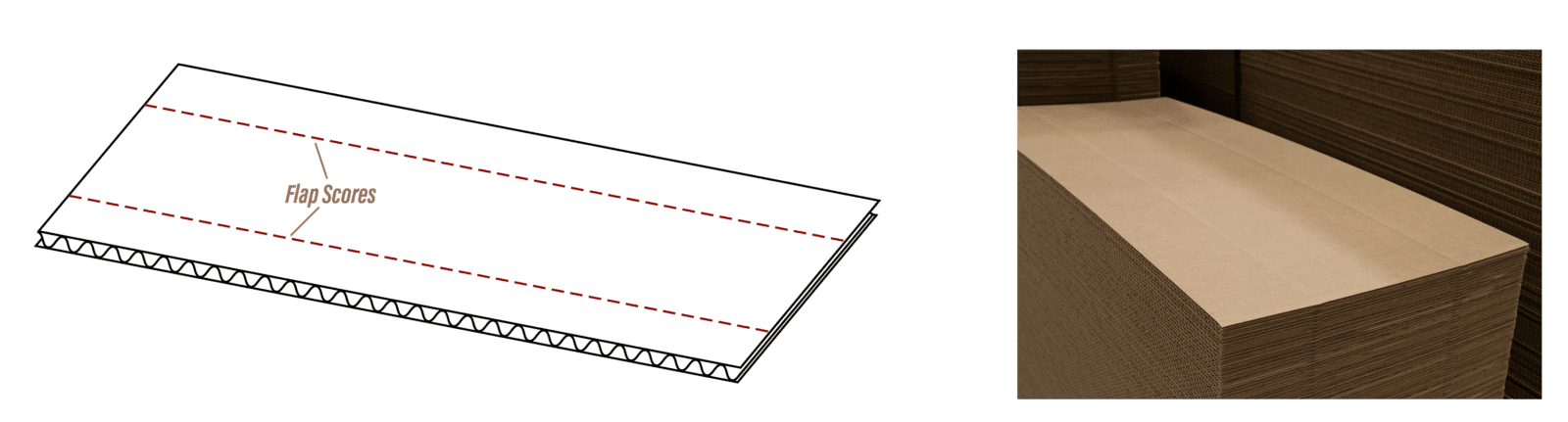

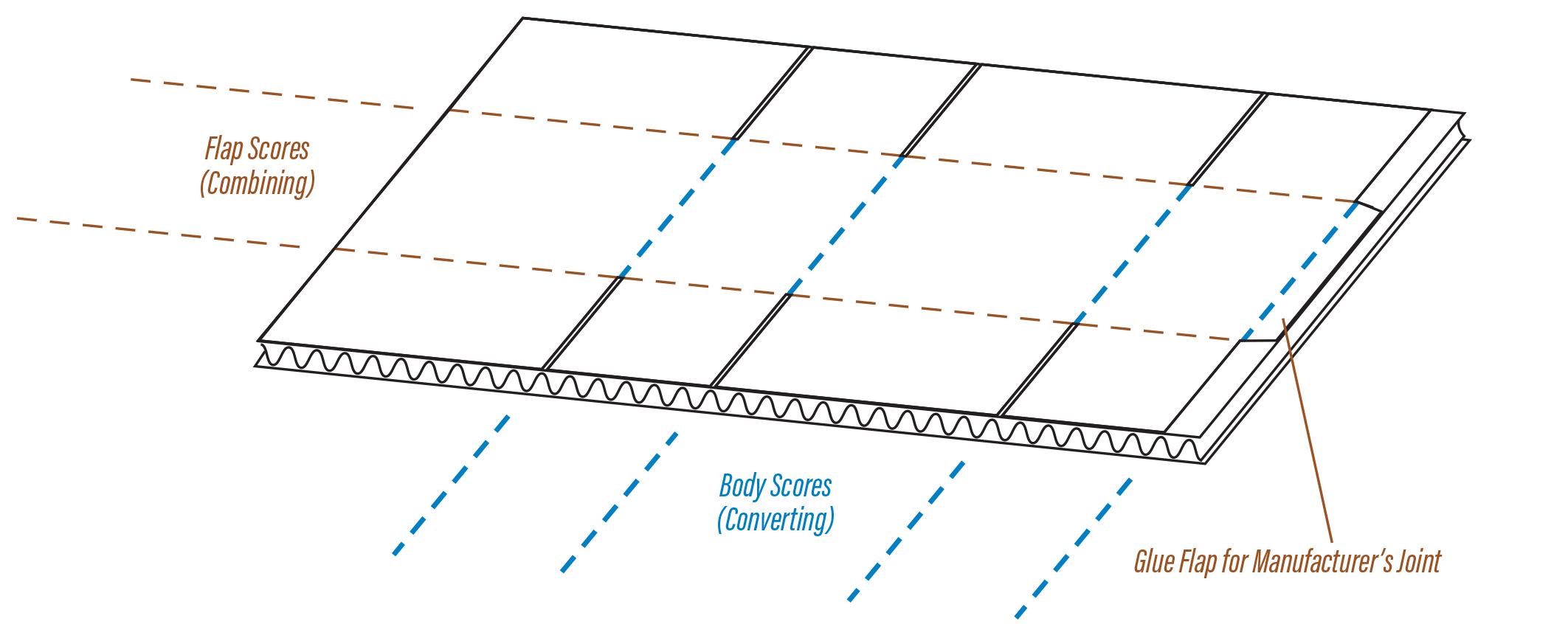

Any folding creases (scores) added inline on the corrugator before the board is cut down into sheets are always parallel to the direction that the paper travels through the machine — crossing the flutes. These scores typically become the flap scores of a finished box.

At the Dry End, the combined board is cut to job-specific sheet sizes and stacked, awaiting conveyance to a converting line.

The combined board product coming off of the Dry End of the corrugator at a Full-Line plant is Work In Process (WIP). It will move on to the converting stations within the plant

The product coming off of a Sheet Feeder’s corrugator is considered Finished Goods for that plant. It will not be converted into boxes on the premises.

Folds, Joints, Angles, Shapes and Graphics

the converting stage—a perpendicular process

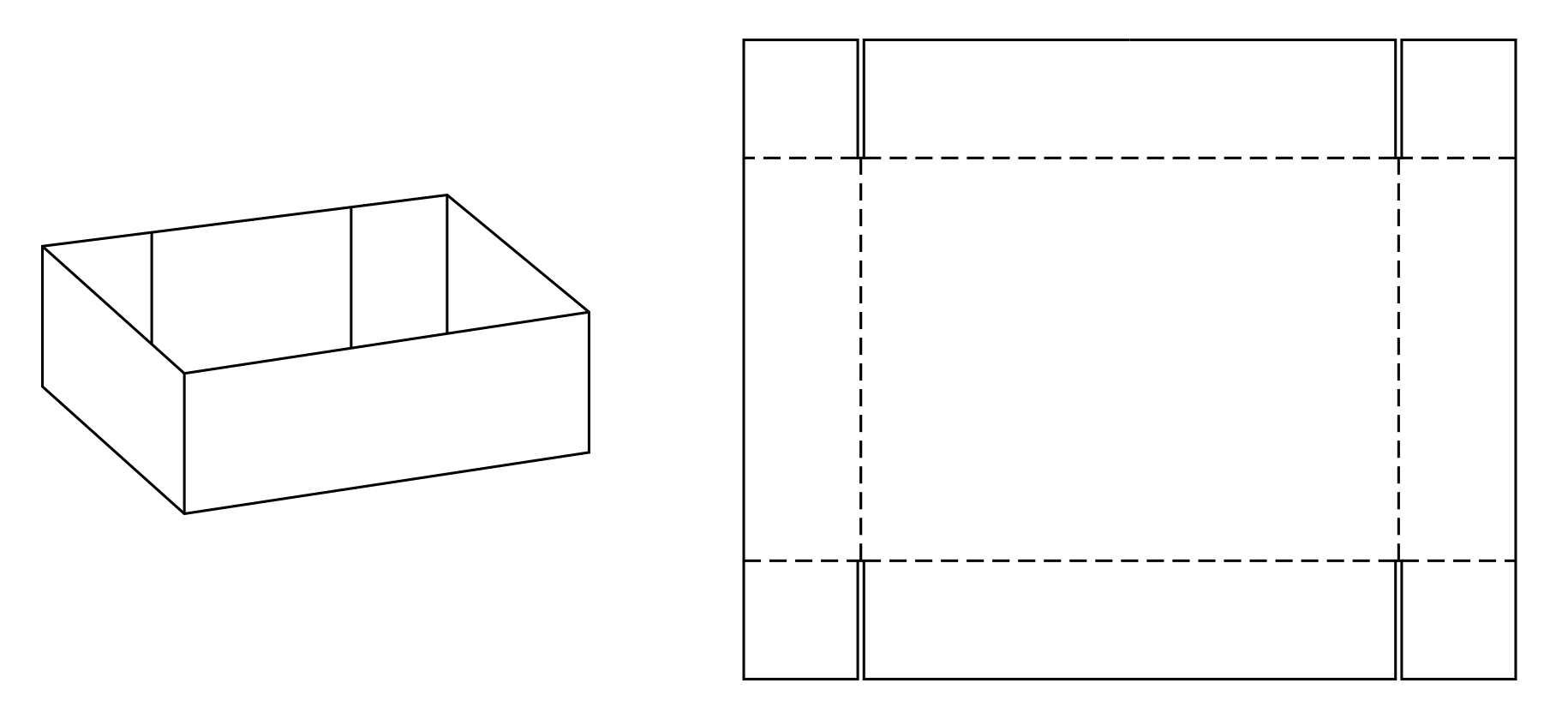

Once the corrugated board has been fully formed and is stacked in cut sheets at the Dry End of the corrugator, it’s ready to go on to converting stations within the plant. Which converting machine receives which cut sheets depends upon the type of box being run and what its attributes and requirements are.

The sheets travel through the converting equipment perpendicular to the direction they traveled through the corrugator.

Not only do the cut sheets travel through converting equipment

perpendicular

to the direction of flow through the corrugating line, but in

many Full-Line plants, entire converting production lines run

perpendicular to the corrugating line.

This

horizontal-to-vertical plan allows for logical, efficient

distribution of Work In Process from the corrugator out to the

various converting stations.

converting equipment is only in FULL-LINE and SHEET plants

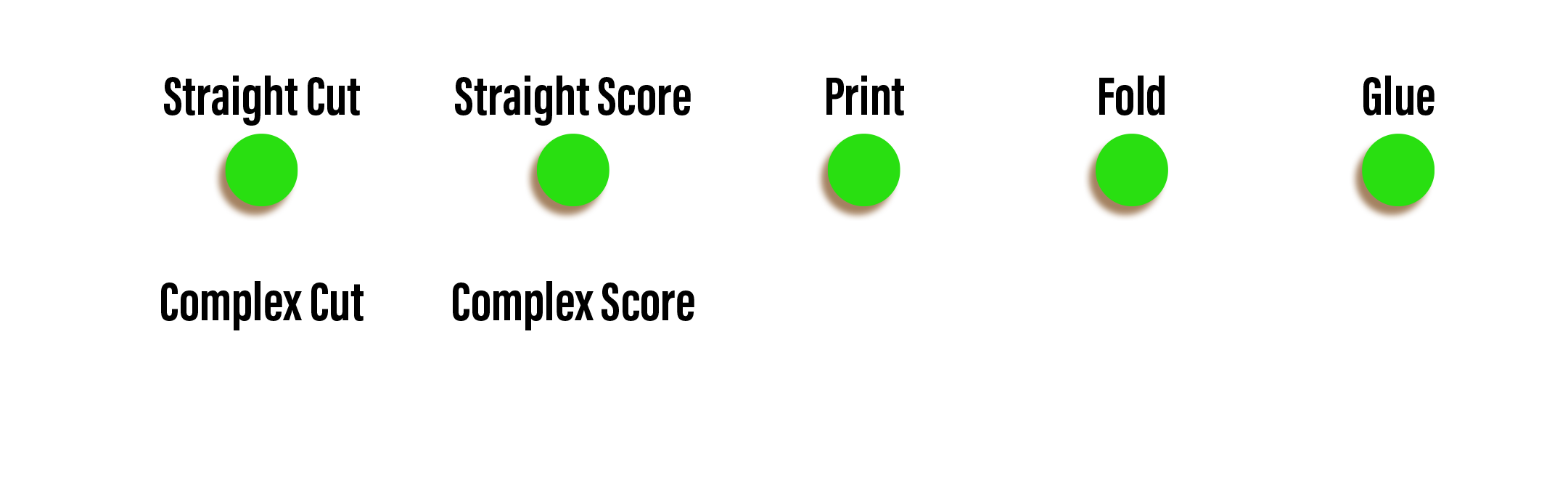

equipment:

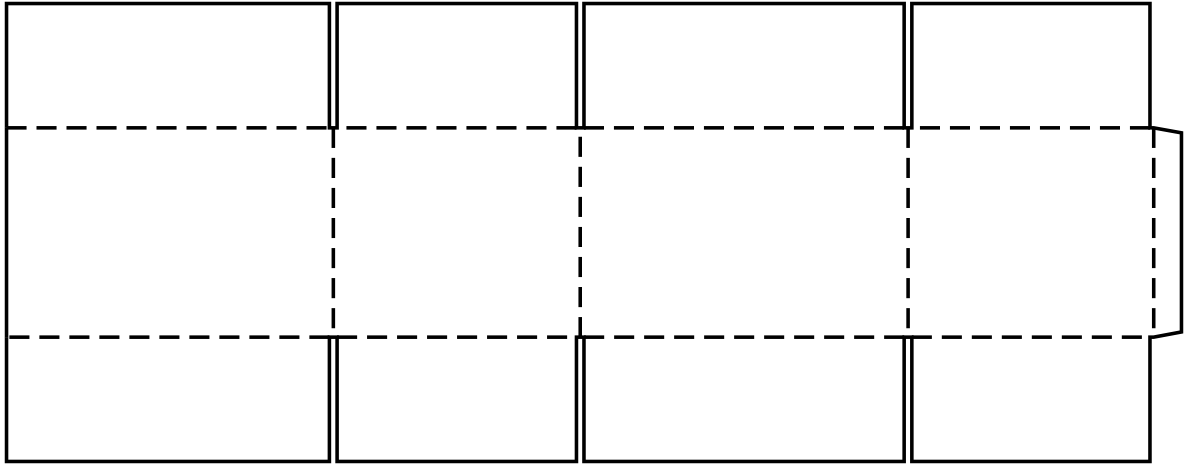

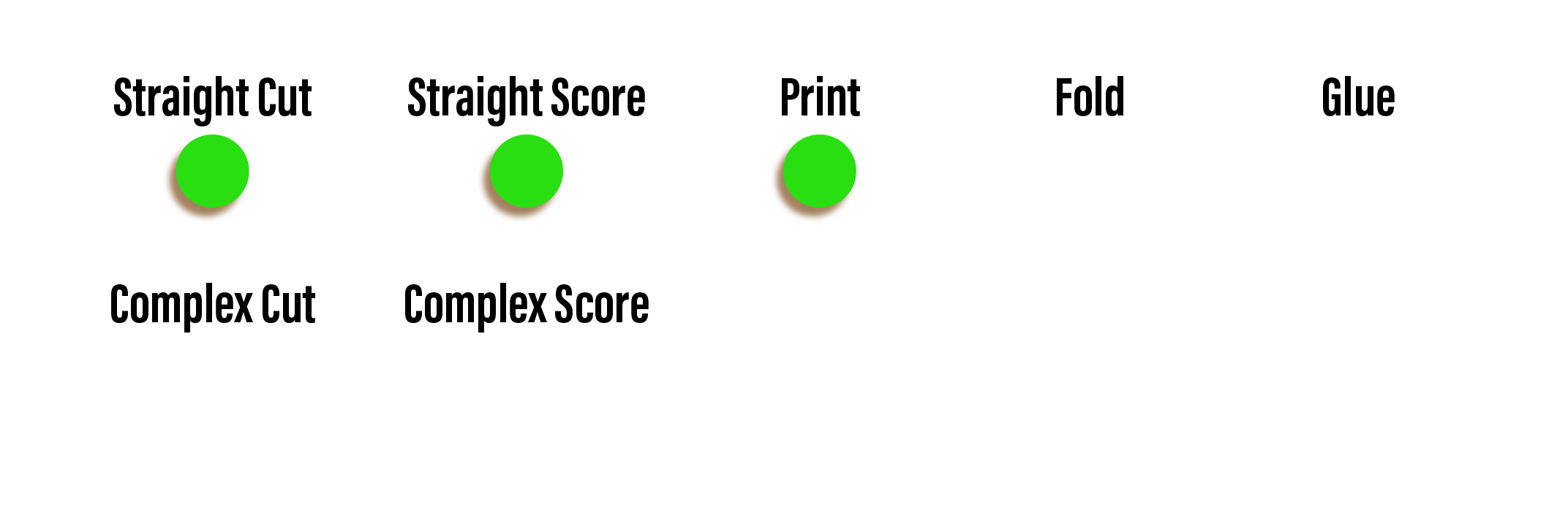

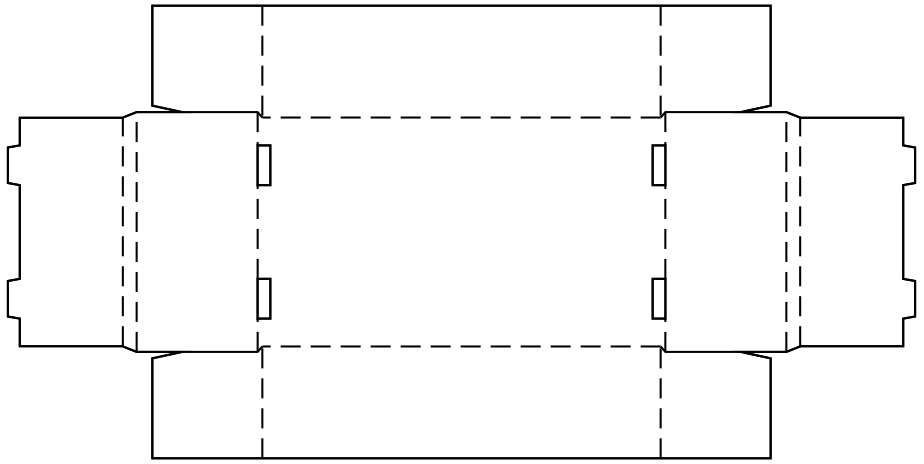

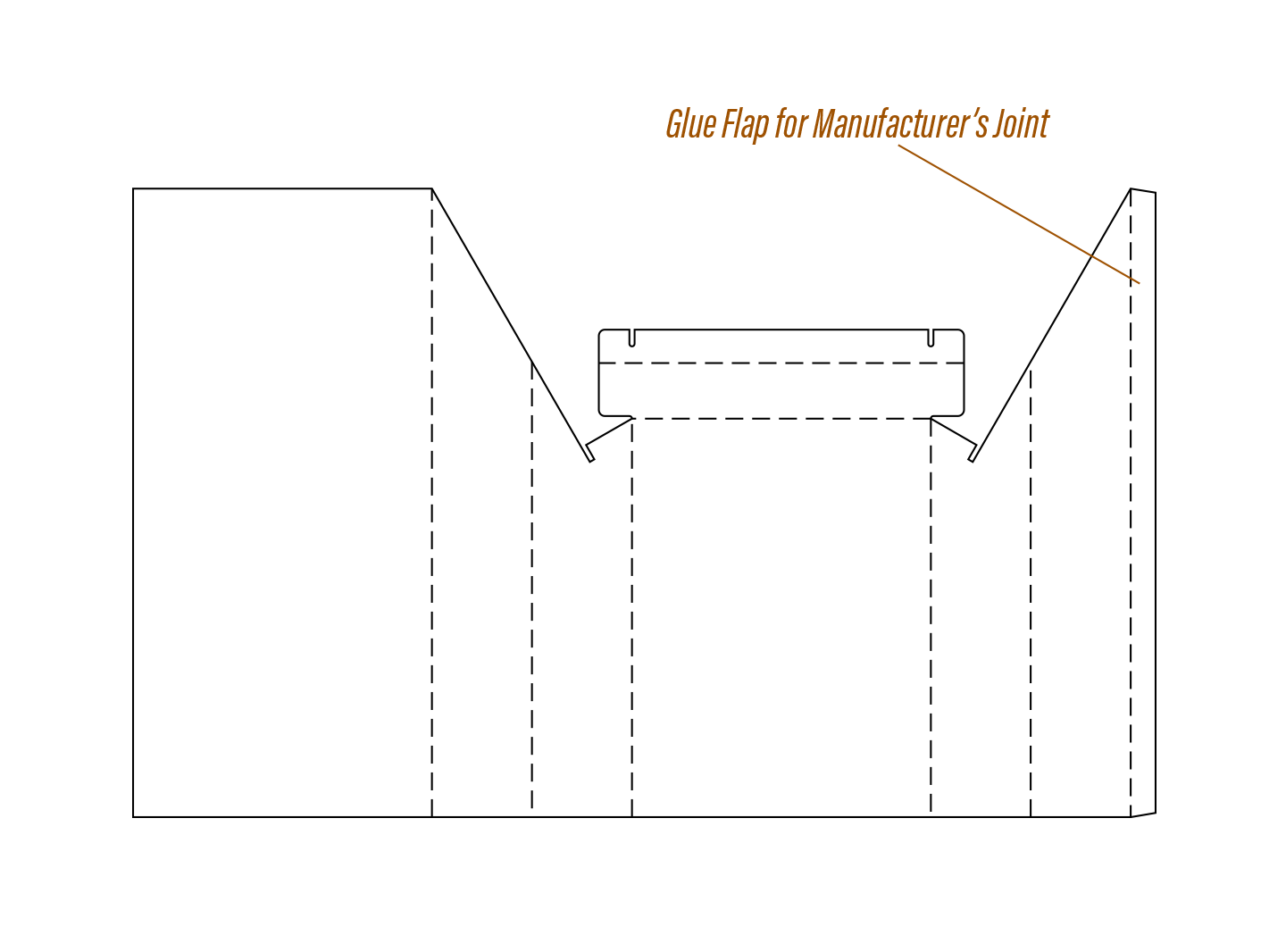

- Makes boxes that have only straight-line cuts and scores and have a “manufacturer’s joint” or “glue joint”

- Uses cutting and creasing “wheels” on a rotating shaft

- Prints on the outside of the box (flexographic printing)

- Folds the box

- Glues the manufacturer’s joint

All scores made by the Flexo Folder-Gluer run perpendicular to any scores made by the corrugator. These scores run in the same direction as the flutes, instead of across them, and will become the body scores of a typical box.

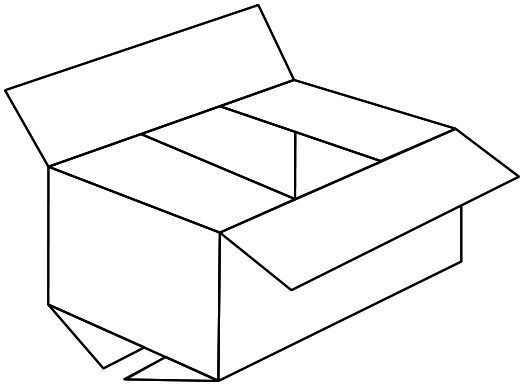

This single machine handles a complete cycle of functions, starting with flat combined sheets with corrugated scores for the flaps, and ending with finished boxes in Knocked Down Flat (KDF) format.

Typical box types coming off of this machine are:

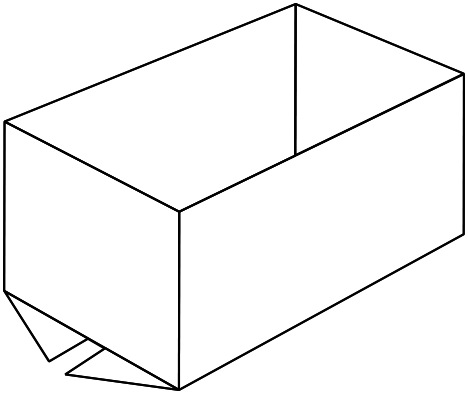

RSC — Regular Slotted Container

HSC — Half Slotted Container

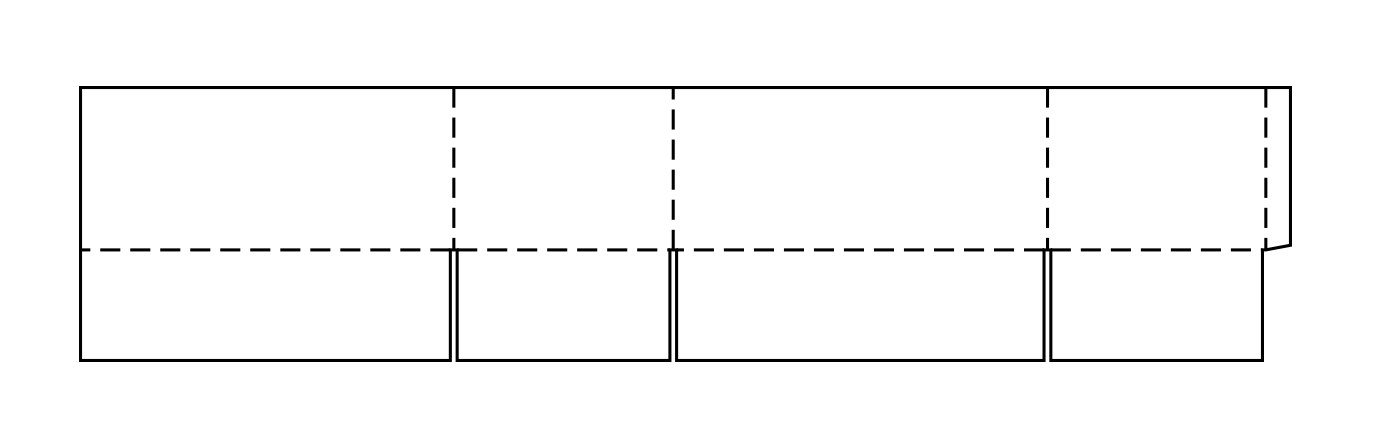

- Makes boxes that have only straight-line cuts and scores, with no manufacturer’s joint

- Uses cutting and creasing “wheels” on a rotating shaft

- Prints on the outside of the box (flexographic printing)

- Does not fold or glue

The Printer-Slotter is used to finish non-glued products such as trays and telescoping boxes.

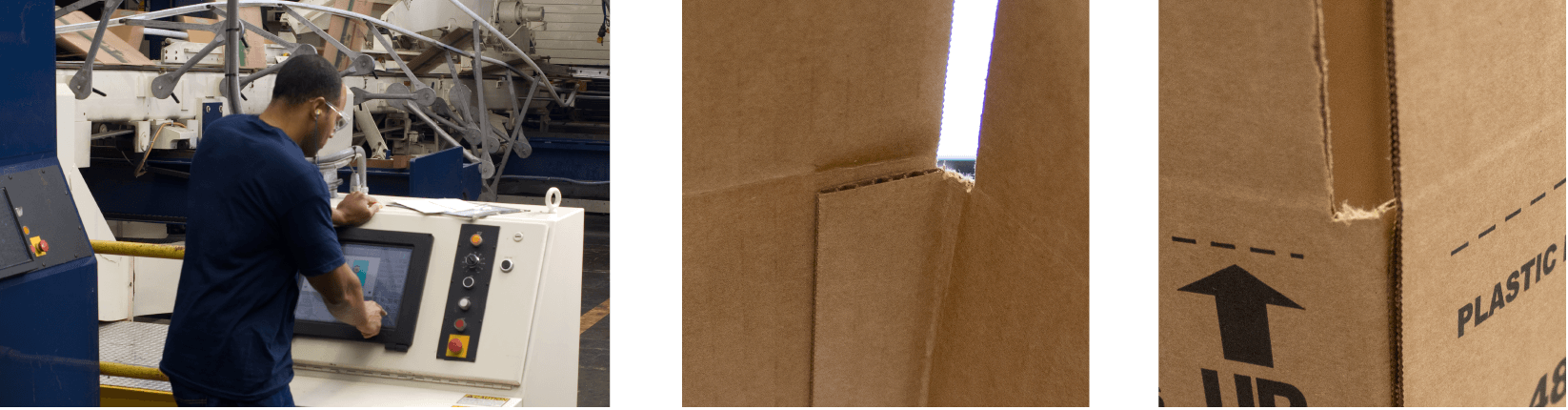

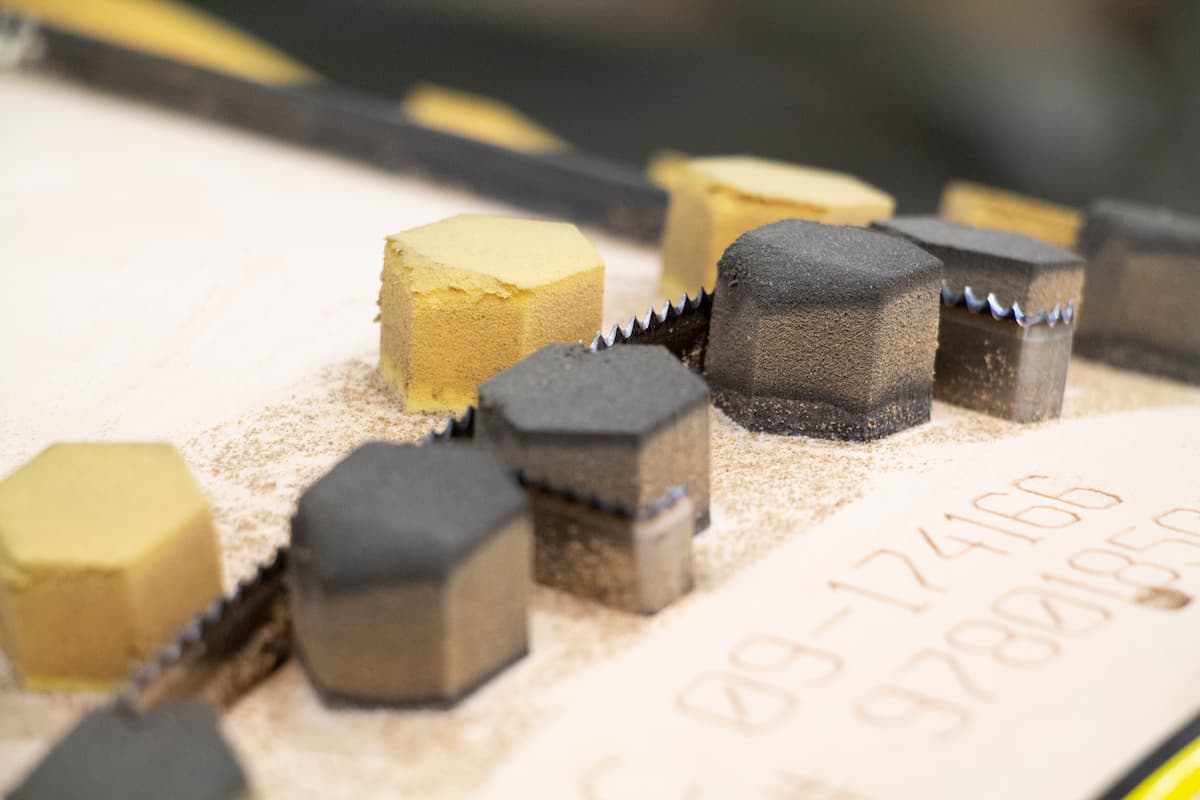

- Makes boxes that can’t be manufactured using straight-line cutting and creasing wheels

- Uses a cutting die, either on a flat bed or affixed to a cylinder

- Prints on the outside of the box

- Does not fold or glue

Die cutters are used for products that require:

- More complex cuts which may include angles, rounded edges, tabs, slots and cutouts

- Scores that allow for folding into shapes that may include angles other than 90 degrees

- Used for gluing die-cut items

- Does not cut, score or print

Any corrugated products that have been cut and scored on a die cutter and also have a glued manufacturer’s joint typically travel flat from the die cutter to a second converting phase on the Folder-Gluer.

Labelers — affix high-quality lithographic labels onto combined sheets

Litho-Laminators — laminate full-size preprinted sheets onto singleface corrugated board

Curtain Coaters — apply a thin film of polymer-wax to the surface of the combined board to serve as a moisture barrier

Wax Cascaders — thoroughly saturate the combined board with a protective wax moisture barrier

Stitchers — staples a manufacturer’s joint to enhance its strength

Preparing to Leave the Plant

Unit loads move on to strapping (and sometimes wrapping and palletizing, depending on the customer’s request). The shipping department takes the loads from there, and they’re out the door.